lntroducing RUN-PATCH

Todays current runway repair methods do not address the cause of the problem – keeping water out. Traditional repair methods use only fills, which are temporarv at best.

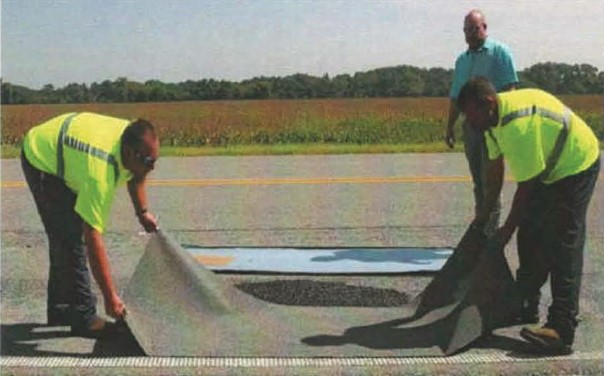

RUN-PATCH is the solution! Take the extra step now and avoid repeat repair work later. RUN-PATCH Peeland sealRepair Patch embeds into the roadway forming a waterproof seal, extending the life of repairs. Unlike traditional methods, RUN-PATCH is a cost effective product that properly contains, strengthens. and seals potholes, crack, and utility cut repairs.